Cov khoom

Kev lag luam zoo heev thiab ib puag ncig kev ua haujlwm ntawm steel qauv enamel xim

Enamel Xim

Pem hauv ntej

Rov qab

Technical Parameters

| Primer | Enamel Txheej Txheej | Varnish (yeem) | |

| Khoom | Solvent | Solvent | Solvent |

| Qhuav zaj duab xis thickness | 100μm-200μm / txheej | 150μm-250μm / txheej | 80μm-120μm / txheej |

| Theoretical kev pab them nqi | 0.15 kg / ㎡ | 0.20 kg / ㎡ | 0.10 kg / ㎡ |

| Kov qhuav | ± 2h (25 ℃) | 8 teev (25 ℃) | ± 2h (25 ℃) |

| Lub sijhawm ziab (nyuaj) | 12 teev | 12 teev | 12 teev |

| Volume solids% | 80 | 85 | 80 |

| Kev txwv kev thov Min.Temp.Max.RH% | (-10) ~ 80 hli | (-10) ~ 80 hli | (-10) ~ 80 hli |

| Flash point | 28 | 38 | 32 |

| Xeev hauv lub thawv | Tom qab stirring, tsis muaj caking, uas qhia ib tug uniform xeev | Tom qab stirring, tsis muaj caking, uas qhia ib tug uniform xeev | Tom qab stirring, tsis muaj caking, uas qhia ib tug uniform xeev |

| Constructability | Tsis muaj teeb meem hauv kev txau | Tsis muaj teeb meem hauv kev txau | Tsis muaj teeb meem hauv kev txau |

| Nozzle lub taub hau (mm) | 1.5-2.0 Nws | 1.5-2.0 Nws | 1.5-2.0 Nws |

| Nozzle siab (Mpa) | 0.1-0.2 hli | 0.1-0.2 hli | 0.1-0.2 hli |

| Dej tsis kam (96h) | Ib txwm | Ib txwm | Ib txwm |

| Acid tsis kam (48h) | Ib txwm | Ib txwm | Ib txwm |

| Alkali tsis kam (48h) | Ib txwm | Ib txwm | Ib txwm |

| Yellowing kuj (168h) | ≤ 3.0 | ≤ 3.0 | ≤ 3.0 |

| Ntxuav kuj | 2000 zaug | 2000 zaug | 2000 zaug |

| Tarnish tsis kam /% | ≤ 15 | ≤ 15 | ≤ 20 |

| Kev pab lub neej | > 10 xyoo | > 10 xyoo | > 10 xyoo |

| Lub sijhawm khaws cia | 1 xyoo | 1 xyoo | 1 xyoo |

| Xim xim | Ntau xim | Ntau xim | Pob tshab |

| Txoj kev thov | Roller, Txhuam los yog Txau | Roller, Txhuam los yog Txau | Roller, Txhuam los yog Txau |

| Cia | 5-30 ℃, txias, qhuav | 5-30 ℃, txias, qhuav | 5-30 ℃, txias, qhuav |

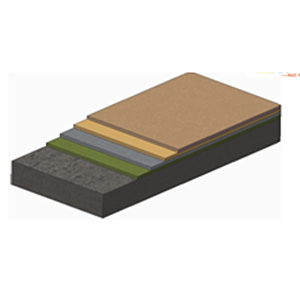

Daim ntawv qhia kev thov

Pre-kho substrate

Primer

Enamel Txheej Txheej

Varnish (yeem)

| Daim ntawv thovScope | |

| Haum rau sab hauv thiab sab nraum zoov hlau tiv thaiv, xws li steel qauv ntawm cov kav dej, hlau rooj tog, marine, kev lag luam kev tsim kho, hluav taws xob kev lag luam, ntsuas kev lag luam thiab lwm yam. | |

| Pob | |

| 20kg / chim thiab 6kg / chim. | |

| Cia | |

| Cov khoom no khaws cia ntawm qhov kub siab tshaj 0 ℃, qhov cua zoo, shady thiab txias qhov chaw. |

Kev qhia ntawv thov

Kev tsim kho

Qhov saum npoo yuav tsum tau polished, kho, plua plav sau raws li qhov chaw yooj yim ntawm qhov chaw;Kev npaj substrate kom raug yog qhov tseem ceeb rau kev ua tau zoo.Qhov saum npoo yuav tsum yog suab, huv si, qhuav thiab tsis muaj cov khoom xoob, roj, roj, thiab lwm yam kab mob.

Kauj ruam thov

Primer:

1) Sib tov (A) primer, (B) curinge agent thiab (C) thinner nyob rau hauv ib lub thoob raws li qhov sib piv ntawm qhov hnyav;

2) Sib tov tag nrho thiab do hauv 4-5 feeb kom txog thaum tsis muaj npuas sib npaug, xyuas kom cov xim yuav tsum tau nplawm tag nrho.Lub hom phiaj tseem ceeb ntawm cov primer no yog kom ncav cuag cov dej los tiv thaiv, thiab kaw lub substrate kom tiav thiab tsis txhob muaj cua npuas hauv lub cev txheej;

3) Kev siv tau yog 0.15kg / m2.Rolling, txhuam los yog tshuaj tsuag cov primer sib npaug (raws li daim duab txuas qhia) los ntawm 1 zaug;

4) Tos tom qab 24 teev, cov kauj ruam tom ntej ntawm daim ntawv thov txheej txheej txheej txheej txheej enamel;

5) Tom qab 24 teev, raws li qhov chaw nyob, polishing tuaj yeem ua tiav, qhov no yog xaiv tau;

6) Kev tshuaj xyuas: xyuas kom cov xim pleev xim yog sib npaug nrog cov xim tsis sib xws, tsis muaj hollowing.

Enamel Txheej Txheej:

1) Sib tov (A) enamel top txheej, (B) curing agent thiab (C) thinner nyob rau hauv ib lub thoob raws li qhov sib piv ntawm qhov hnyav;

2) Sib tov tag nrho thiab do hauv 4-5 feeb kom txog thaum tsis muaj npuas sib npaug, xyuas kom cov xim muaj zog;

3) Kev siv tau yog 0.25kg / m2.Rolling, txhuam los yog tshuaj tsuag cov primer sib npaug (raws li daim duab txuas qhia) los ntawm 1 zaug;

4) Kev tshuaj xyuas: xyuas kom cov xim pleev xim yog sib npaug nrog cov xim sib xws, tsis muaj hollowing.

Nco tseg:

1) Cov xim sib xyaw yuav tsum siv li ntawm 20 feeb;

2) Khaws 1 lub lis piam, tuaj yeem siv tau thaum cov xim muaj zog kiag li;

3) Kev tiv thaiv zaj duab xis: kom deb ntawm kev taug kev, los nag, raug tshav ntuj thiab khawb kom txog thaum cov yeeb yaj kiab tau qhuav thiab ruaj khov.